Product Description:

Stainless Steel Tubing stands as a versatile and essential component across a wide range of industries, offering exceptional strength, durability, and corrosion resistance. Manufactured from high-quality stainless steel, this tubing is designed to meet the rigorous demands of various applications, making it an indispensable material in modern engineering and manufacturing processes. With an outer diameter range spanning from 6mm to an impressive 2500mm, our stainless steel tubing caters to both small-scale precision projects and large industrial requirements.

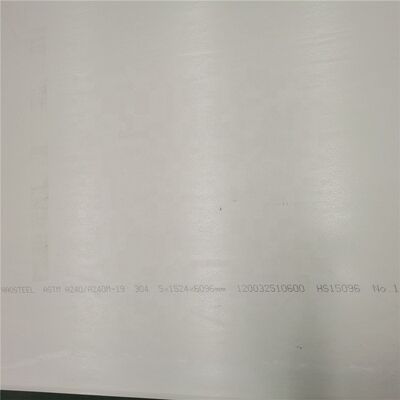

One of the key features of our Stainless Steel Tubing is the variety of surface finishes available. Customers can choose from 2B, BA, NO.1, NO.2, and NO.4 finishes, each providing unique aesthetic and functional properties. The 2B finish offers a smooth, matte surface ideal for general applications, while the BA finish delivers a bright, reflective surface perfect for decorative purposes. NO.1 and NO.2 finishes provide a rougher, annealed surface suitable for heavy-duty and industrial use, and the NO.4 finish offers a brushed appearance that combines durability with a sleek look. These surface finish options ensure that the tubing can be tailored to meet specific project requirements, whether for visual appeal or enhanced performance.

Our Stainless Steel Tubing is produced using advanced welded seamless production techniques, guaranteeing high structural integrity and uniformity throughout the tube’s length. Seamless tubing is especially valued in applications requiring high pressure resistance and minimal risk of leakage, making it a preferred choice for critical environments. Additionally, our welded tube offerings encompass sizes ranging from 10mm OD to 1520mm OD, providing flexibility for various engineering challenges. This wide size range ensures that whether you need a compact, precision tube or a large-diameter pipe, our products can accommodate your needs.

In the automotive sector, Automotive Stainless Steel Tubing is widely recognized for its robustness and resistance to corrosion, heat, and mechanical stress. These properties make it ideal for exhaust systems, fuel lines, hydraulic systems, and structural components within vehicles. The use of stainless steel tubing in automotive manufacturing not only extends the lifespan of vehicle parts but also enhances safety and performance. Our tubing's superior quality and reliability have made it a trusted choice among manufacturers seeking long-lasting and efficient solutions.

Moreover, our Stainless Steel Tubing is often compared and used interchangeably with Alloy Steel Tube in various industrial applications. Alloy Steel Tubes are known for their enhanced mechanical properties achieved through alloying elements, and when combined with the corrosion resistance of stainless steel, they offer exceptional performance in demanding environments. Our product range includes both stainless steel and alloy steel tubes, ensuring that clients receive the optimal material suited to their specific requirements.

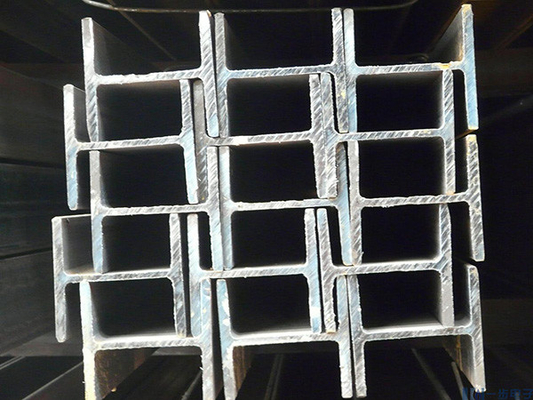

In addition to automotive and industrial applications, our Alloy Steel Tube and Stainless Steel Tubing serve vital roles in construction, chemical processing, oil and gas, food and beverage, and medical industries. Their durability, resistance to extreme temperatures, and hygienic surface finishes make them highly adaptable and reliable across multiple sectors. Whether used as structural supports, conduits for fluids, or protective coverings, these tubes provide unmatched quality and performance.

Choosing our Stainless Steel Tubing means investing in a product that combines cutting-edge manufacturing processes with premium materials. The seamless welded production technique ensures minimal defects and superior strength, while the diverse outer diameter options and surface finishes allow for extensive customization. Whether your project demands the toughness of alloy steel tube or the corrosion resistance of stainless steel, our tubing solutions are engineered to exceed expectations.

In summary, our Stainless Steel Tubing product line offers an extensive range of sizes from 6mm to 2500mm outer diameter, multiple surface finish options including 2B, BA, NO.1, NO.2, and NO.4, and is produced using high-grade stainless steel through welded seamless technology. With welded tubes available from 10mm OD to 1520mm OD, we provide flexibility and quality for diverse industrial needs. Highly regarded in the automotive industry as Automotive Stainless Steel Tubing and comparable in performance to Alloy Steel Tube, our products are designed to deliver excellence, reliability, and durability in every application.

Applications:

HAOSTEEL Stainless Steel Tubing, manufactured in Zhejiang, is a premium product available in a wide range of models including 201, 202, 301, 304, 304L, 309S, 316, 316L, 310S, 321, 347H, 317L, 316Ti, 2205, 2507, 904L, 254SMO, 410, 420, 430, and 430F. These tubes are crafted from high-quality alloy steel and are produced using advanced welded and seamless production techniques, ensuring exceptional strength, durability, and corrosion resistance. With outer diameters ranging from 6mm to 2500mm, HAOSTEEL’s stainless steel round tubes, such as the 304, 304L, 316, and 316L models, are ideal for a variety of industrial and commercial applications.

The versatility of HAOSTEEL’s stainless steel tubing makes it suitable for numerous application occasions and scenarios. Austenitic Stainless Steel PipeTube, known for its excellent corrosion resistance and formability, is widely used in the chemical, food processing, and pharmaceutical industries where hygiene and durability are paramount. Its resistance to high temperatures and corrosive environments also makes it a preferred choice for heat exchangers, boilers, and pressure vessels.

In addition to austenitic types, HAOSTEEL offers Duplex Stainless Steel Tube options such as models 2205 and 2507, which combine the best features of austenitic and ferritic stainless steels. These duplex tubes provide superior strength and resistance to stress corrosion cracking, making them ideal for use in offshore oil and gas platforms, marine applications, and aggressive chemical processing environments. Their robust nature allows for reduced wall thickness, saving weight and cost without compromising performance.

HAOSTEEL also supplies Stainless Steel Square Tubing, which is highly sought after for architectural, structural, and automotive applications. The square tubing’s uniform shape and sturdy construction make it perfect for building frameworks, handrails, and decorative elements that demand both aesthetic appeal and structural integrity. Its corrosion resistance ensures longevity even in harsh outdoor conditions.

With a minimum order quantity of just 1 ton and competitive pricing ranging from 1500 USD to 3000 USD, HAOSTEEL stainless steel tubing is accessible for both small-scale projects and large industrial orders. Additionally, the company accepts third-party inspections to guarantee product quality and compliance with international standards. Whether for high-performance industrial machinery, construction, or specialized manufacturing, HAOSTEEL’s extensive range of stainless steel tubing solutions meets diverse needs with reliability and excellence.

Customization:

HAOSTEEL offers premium Stainless Steel Tubing with a wide range of models including 201, 202, 301, 304, 304L, 309S, 316, 316L, 310S, 321, 347H, 317L, 316Ti, 2205, 2507, 904L, 254SMO, 410, 420, 430, and 430F. Our products are manufactured in Zhejiang, ensuring top quality and reliability.

We specialize in both Welded and Seamless Stainless Steel Tubing with a diameter range of 3-12mm. Our tubing is made from high-grade stainless steel material suitable for various applications, including Automotive Stainless Steel Tubing and Ferritic Stainless Steel Tube requirements.

The minimum order quantity is 1 TON, with prices ranging from 1500 USD to 3000 USD depending on specifications and order volume. We provide invoicing based on actual weight and accept third-party inspections to guarantee product quality.

Our 316L Stainless Steel Tubing is particularly popular for its excellent corrosion resistance and durability, making it ideal for demanding industrial uses. Trust HAOSTEEL for customized stainless steel tubing solutions tailored to your needs.

Packing and Shipping:

Our Stainless Steel Tubing is carefully packaged to ensure maximum protection during transit. Each tube is individually wrapped with protective material to prevent scratches and damage. The tubes are then securely bundled and placed in sturdy, reinforced cartons designed to withstand handling and shipping stresses.

For shipping, we use reliable carriers to deliver the product safely and promptly to your destination. All packages are clearly labeled with handling instructions and product details to facilitate smooth delivery. We also offer customized packaging solutions upon request to meet specific requirements.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!